ISO CNC Full Auto Nc Semi Automatic Electric Tube Bending Machine Free Mold Stainless Steel Aluminum Hydraulic Mandrel Pipe Bender

Description

Basic Info.

| Model NO. | Customized |

| Applicable Material | Carbon Steel/Stainless Steel/Copper/Aluminum |

| Applicable Shape | Oval/Square/Rectangle/Round |

| Warranty | 3 Years |

| Control | Numerical Control |

| Operation | Easy |

| Voltage | Customized/Standard |

| Maxi. Capacity | 38mmx2mm |

| Mandrel | According to Product Drawing |

| Machine Type | Pipe Bending Machine Tube Bender |

| Feed | Manual Automatic |

| Bending | Hydraulic/Servo |

| Product Name | Tube Bending Machine |

| Item | Semiautomatic Nc Pipe Bending Machine |

| Motor Power | 5.5kw |

| Color | Customized |

| Certification | ISO 9001:2008, CE |

| Suitable for | Metal Tube Pipe |

| Function | Pipe and Tube Bending |

| Transport Package | Iron Pallet |

| Specification | Customized |

| Trademark | WONSTEN |

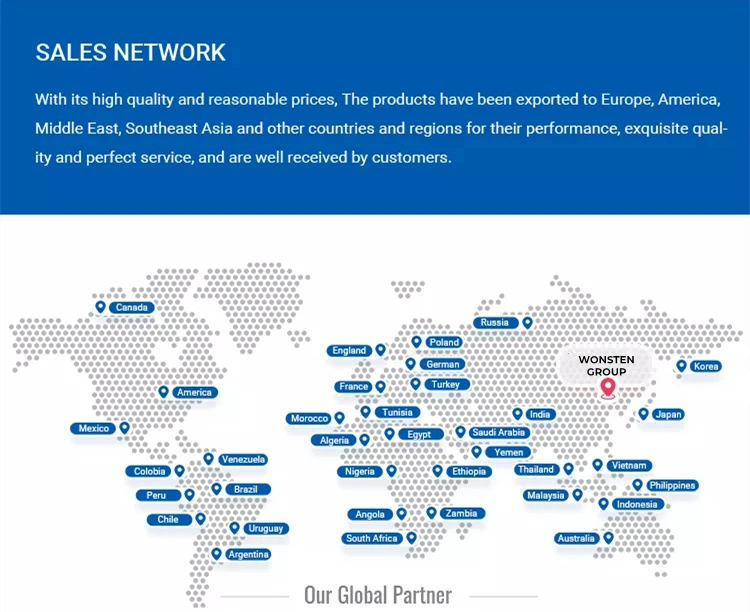

| Origin | China |

| HS Code | 8462991000 |

| Production Capacity | 500 PCS Per Month |

Packaging & Delivery

Package Size 220.00cm * 100.00cm * 100.00cm Package Gross Weight 2000.000kgProduct Description

|

The semiautomatic pipe bender of our NC Pipe Bending Machine has hydraulic bending shaft, manual bending shaft and manual rotating shaft. The man-machine interface enables you to automatically enter information and walking mode. All hydraulic movements on clamping die, pressure die and mandrel, with high and reliable performance.

The multi-layer storage box of our NC Pipe Bending Machine realizes the function to store the finished rebar after processing. The import control system is convenient and quick. It can set up continuous work tasks, can handle multiple angles in one cycle, and has a task storage function. The imported inverter is used to control the bending motor, which can adjust the bending speed, and control the accuracy of the bending angle through the encoder. Due to the high performance, it is available of high speed operation and there is no special need of maintaining.

| Model | Unit | DW38NCB | DW50NCB | DW75NCB | DW89NCB | DW114NCB |

| Maxi. Diameter ×thickness | mm | Φ38×2 | Φ50×3 | Φ75×4 | Φ89×5 | Φ114×15 |

| Maxi. Bending radius | mm | R260 | R330 | R400 | R510 | R650 |

| Mini. Bending radius | mm | R15 | R20 | R30 | R40 | R90 |

| Maxi. Bending angle | 190° | 190° | 190° | 190° | 190° | |

| Standard mandrel length | mm | 1600 | 2200 | 2800 | 3800 | 5500 |

| Control system | Microcomputer | |||||

| Maxi. Bender numbers | pcs | 16 | 16 | 16 | 16 | 16 |

| Parts in store | pcs | 16×16 | 16×16 | 16×16 | 16×16 | 16×16 |

| Hydraulic motor power | kw | 4 | 5.5 | 7.5 | 11 | 18.5 |

| Maxi. System pressure | mpa | 12 | 12 | 14 | 14 | 14 |

| Hydraulic system control | Solenoid valve | |||||

| Contain capacity | L | 110 | 150 | 240 | 320 | 420 |

| Size | mm | 2600× 600×1200 | 3000× 700×1300 | 3650× 1000×1400 | 4400× 1150×1400 | 7500× 1300×1450 |

| Weight | kg | 750 | 1220 | 3500 | 4500 | 6500 |

Our Contact