New Customized CE ISO Electro

Description

Basic Info.

| Model NO. | Smart SSP |

| Certification | ISO 9001:2008, CE |

| Automation | Automatic |

| Suitable for | Copper, Aluminum, Alloy, Carbon Steel, Stainless Steel |

| Type | Hydraulic Bending Machine |

| Working Speed | 10mm/S |

| Main Motor Power | 13.2kw |

| Return Speed | 100mm/S |

| Machine Diamentions | L 3500mm / W 1650mm /H 260mm |

| Machine Wight | 12t |

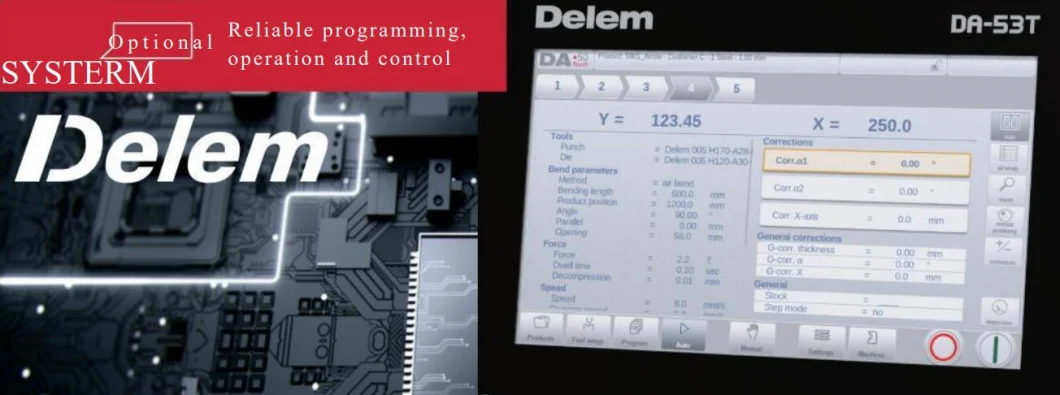

| CNC System | Da53t |

| Maximum Opening Height | 420mm |

| Fast Down Speed | 100mm/S |

| Column Spacing | 2700mm |

| Foldable Plate Width | 3200mm |

| Slide Stroke | 200mm |

| Nominal Pressure | 1750kn |

| Transport Package | Standard Export Wooden Case |

| Specification | 12 T |

| Trademark | Hgstar |

| Origin | Wuhan, Hubei. China |

| HS Code | 8463300000 |

| Production Capacity | 500sets/Month |

Packaging & Delivery

Package Size 350.00cm * 165.00cm * 260.00cm Package Gross Weight 12000.000kgProduct Description

HG-SSP Series Electro-hydraulic Single Servo CNC Bending MachineProduct Description

Bending machine is used to bend the cold metal plate into various geometric cross-sectional shapes by using the equipped dies (general or special dies). Electro-hydraulic servo synchronous CNC bending machine is controlled by professional advanced CNC system and equipped with deflection compensation device, which is very simple and convenient to operate and requires little experience for operators. You don't need to set out manually, and you can bend and calculate automatically if you have drawings and input the correct step size. Compared with the torsion axis bending machine, it liberates a lot of manpower and relieves the excessive dependence of bending work on manual experience.

Detailed Photos

SVP Energy Saving SystemEnergy saving: servo pump system is to supply oil on demand, greatly improving theenergy saving effect.Reduce noise: servo pump system only when needed to rotate, comprehensive noisedropped by 30%.Reduce oil temperature: the torque limit and analog speed control mode, eliminate thesectional flow valve and the overflow, greatly reduce the oil temperature.High Precision Grating RulerUsing high precision grating ruler as a displacement sensor,Ann in C plate, used todetect oil cylinder position, feedback accuracyup to 0.001 mm, which helps better controlthe bending Angle.

CNC X axis and R axis Accurate PositioningAxis X is driven by linear guide rail, ball screw and servo motor to ensure accurate positioning of X axis.R shaft adopts high-power servomotor drive, linear guide and ball screw, have fast response, the characteristics of the positioning precision.

Servo CNC Rear StopperHigh strength aluminum alloy body, servo motor driven, all tracks are linear guide and ball screw.Highprecision, high speed, low noise, dust free maintenance and fast response.

Product Advantages

1.Airframe adopt fission steel platewelded structure, the large temperingfurnace equipment tempering treatment,eliminate the welding stress and stresscaused by variable form, ensure the accuracy of machine tool stability.2.The fuselage, the slider, and otherimportant parts adopt finite elementanalysis software ANSYS to carry on the analysis, to ensure the reliability of the machine tool.3.On both sides of the main oil cylinder synchronization using imported electrohydraulic servo valve and single grating ruler Spain FAGOR company constitute a closed loop control, feedback precision, slider running accurately, thus repositioning of pure bending precision, slider degree is high.4.Hydraulic system adopt imported integrated control system, reduce the piping installation, improve the working stability of the machine tool, beautiful appearance is concise.Can be segmented mold, can be assembled into a certain length, according to the requirement of the workpiece machining of to meet the special need, the model USES the security channel structure (European standard), lower die adopts modular structure to adapt to the needs of different artifacts.5.Behind the fully functional organization, can choose behind control multiple axis.The features in the behind, such as guide rail,screw, bearing all use importedparts, ensure that after the keep-off keep-off precision.6.On both sides of the fuselage with C plate, high precision grating ruler is installed on the C plate, avoiding the bending moment change xing folded the precision of bending.7.Airframe adopt fission assembled structure, facilitate the transportation,easy to machining, can ensure the machine precision of whole machine,the machine processing.8.Professional manufacturer of oil cylinder, Germany into a set of imported sealing ring,Germany imports of pipe joint, to overcome the leakage.

Product Parameters

| No | Configuration | Numerical value | unit | Remark | |

| 1 | Nominal pressure | 1350 | KN | ||

| 2 | Foldable plate width | 3200 | mm | ||

| 3 | Slide stroke | 200 | mm | ||

| 4 | Maximum opening height | 420 | mm | ||

| 5 | Column spacing | 2700 | mm | ||

| 6 | throat depth | 400 | mm | ||

| 7 | Fast down speed | 160 | mm/ s | ||

| 8 | Return speed | 130 | mm/ s | ||

| 9 | Working speed | 10 | mm/ s | ||

| 10 | Main motor power | 11 | Kw | servo motor | |

| 11 | CNC system | DA53T | Netherlands | ||

| 12 | X-axis travel of rear stopper | 500 | mm | ||

| 13 | Number of control axes | 4+ 1 Axis (Y1 ,Y2 ,X ,R+V) | |||

| 14 | Machine tool accuracy | Slider repeat accuracy | ≤±0.01 | mm | |

| 15 | Slide positioning accuracy | ≤±0.02 | mm | ||

| 16 | Workpiece straightness | 0.3 / m | mm | ||

| 17 | Bending angle error | <±30 | ′ | ||

| 18 | Raster scale resolution | 0.005 | mm | ||

| 19 | Rear retaining material | X-axis travel | 500 | mm | |

| 20 | X-axis speed | 200 | mm/s | ||

| 21 | positioning accuracy | ±0.05 | mm | ||

| 22 | Repetitive positioning accuracy | ±0.015 | mm | ||

| 23 | Machine wight | 10 T | T | ||

| 24 | Machine diamentions | L 3500 / W 1580 /H 2500 | mm | ||

Sample

Equipment Installation and Debugging:

1. The supplier shall provide the purchaser with technical services such as the basic diagram of the equipment, schematic diagrams of water, electricity, gas and installation requirements within 10 days after signing the contract.2. After the equipment is assembled in the supplier's factory, promptly notify the purchaser to send personnel to the supplier's site for pre-acceptance; and promptly notify the purchaser to make preparations for the installation and commissioning of the equipment at the purchaser's site.3. The supplier provides free installation and commissioning services of the machine, and the buyer provides the necessary auxiliary facilities such as machine hoisting equipment and scaffolding and several auxiliary workers.4. After the equipment is installed and debugged at the buyer's site, the final acceptance of the equipment is carried out.

Personnel training:

1. The supplier assigns professional and technical personnel to provide technical training for the buyer's operators free of charge.2. The first stage: During the installation and commissioning period, at the user site, combined with the commissioning, use and programming of the equipment, the operators, maintenance personnel and technicians will be trained for 2 days, so that the relevant personnel of the user's operation have the ability to use the equipment proficiently. ability.3. The second stage: After three months of normal operation of the equipment, if the demander needs it, the supplier can improve the training of maintenance personnel, operators and technicians again, so that the relevant personnel have the ability to troubleshoot and maintain the equipment, and improve their performance. Operating and programming skills.

Company Profile

About Us

HG star is the pioneer and leader of laser industrial application in China, world's leading provider both of laser equipment and intelligent manufacturing solutions, and the core subsidiary of the well-known national high-techlisted company HGTECH, with the ISO9001 quality management system certification, IS014001 environmental management systemcertification, ISO45001 occupational health and safety system certification.

To meet the actual needs of customers in various fields and multiple scenarios, we continuously enrich products and solutions, expanding the whole industry chain layout of "laser+intelligent manufacturing". With 4 overseas R&D centre and more than 100 senior experts in the laser industry, we focus on breakthroughs incore technologies and carry out forward-looking process technology. In addition to the high quality, we provide top level after-sales service. All the core components are guaranteed for three years and we have 23 worldwide service centre that ensure quick respond tocustomer's problem.

Company certification Business Partners: Exihibition

FAQ

Q: What's the package?

A: We have 3 layers package. For the outside, we adopt wood craft case. In the middle, the machine is covered by foam, to protect the machine from shaking. For the inside layer, the machine is covered by thickening plastic bag for waterproofQ: Will the package damaged during transportation?

A: Our package is considerate all the damage factors and make it to be safe, and our shipping agent have full experienced in safe transportation. We have exported to 180 countries worldwide. So please don't worry, you will receive the parcel in good condition. Q: How to install and run the machine?

A: Our technician have installed the machine before shipping. For some small parts installation, we will send detail training video, user's manual along with the machine. 95% customers can learn by themselves

Q: How can I do if the machine goes wrong?

A: If confronted with such problems, please contact us asap and do not try fix the machine by yourself or someone else. We will response within 24 hours as quick as we can to solve it for you.Please advise us the following information, then we can recommend you the most suitable model, right now, don't hesitate to contact -China HG STAR!

Next: Rt

Our Contact